Intro

This episode is going to be a little different from the rest because it’s going to focus on something that went horribly wrong with the V2 while working on what was going to be this episode.

Full Overview

Watch the overview video or keep reading the full article below

Table of Contents

The Problem

So it all started while I was printing a part for a new project, annoyingly this was the one time I wasn’t recording the actually print process. A came back to the printer after 5 minutes to check on it just to find the printer going and going with only a small portion of the print actually done and a mess of melted filament on top of what it managed to print. I immediately hit the emergency stop button on the control box and started cursing up storm. Now it was time to troubleshoot what went wrong and hopefully come up with a fix.

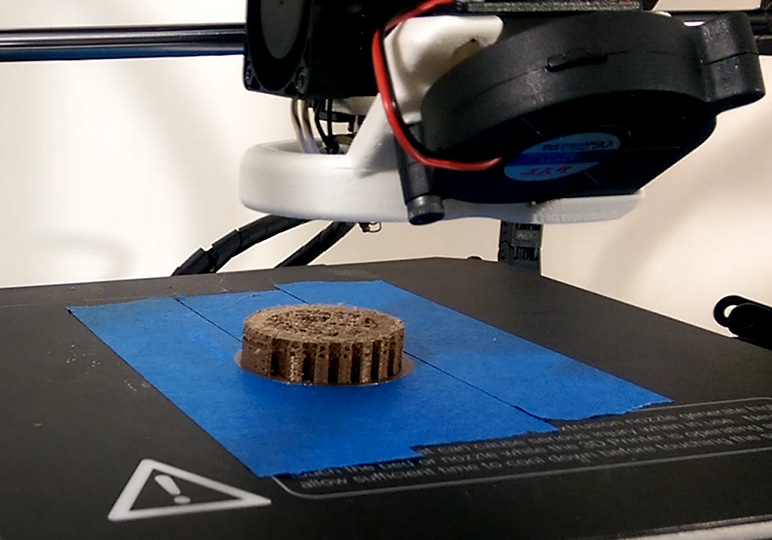

In this kind of scenario the first thing to check is the filament supply but I still had plenty left. Since I wasn’t around when the initial problem started I decided to see what would happen if I tried to print something else. So I started to print a simple part and this is what came out. As you can tell this print is a complete a failure, no clean layers, fragile, basically just a husk. This is a clear sign of under extrusion, which basically means there is not enough material being extruded to make a solid layer.

Troubleshooting

There are several faults that can cause under extrusion like software settings or a clogged nozzle but luckily I observed something early in the printing that ruled out these issues. I noticed that the feeder motor was spinning normally but the filament itself wasn’t moving. Typically I can sense the vibration of the motor in the filament as it runs but this wasn’t the case. I was also able to push the filament through the nozzle without much force which ruled out a clogged nozzle. Since I printed this piece before successfully I doubt it was a software issue, so I figured there must be something wrong with either the filament guide internally, the feeder motor, or the feeder gear. Either way I would be looking at disassembling the primary filament feed of the V2 to figure it out. Without any real direction or instruction I just went for it.

Disassembly

The first thing I did was to of course turns off the printer, unplug it, and make sure it had cooled down. Next I unplugged both fans and the feeder motor.

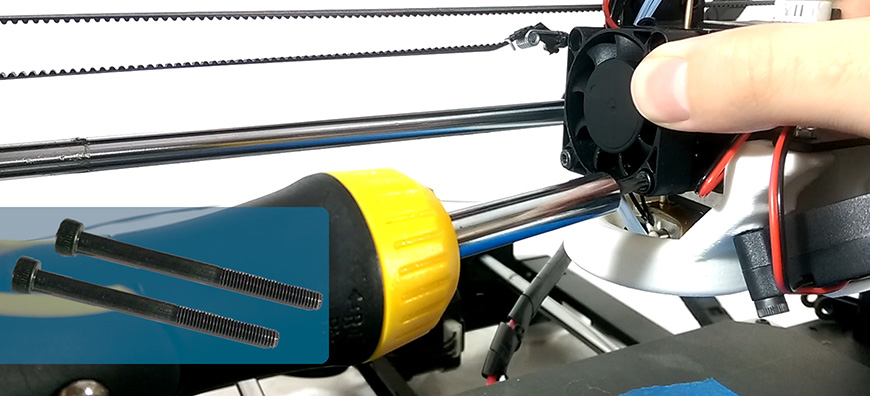

I figured if I remove the side fan and heat sink first I would be able to see what the issue maybe with the filament and feeder. To my surprise the 2 screws that hold the side fan and heat sink in place also sandwiches everything together including the feeder motor. The screws pass through the fan, the heat sink, the nozzle plate, and finally end in the motor housing so if you plan on dissembling the V2 make sure to hold all these pieces together as you unscrew the bolts. Oh and these screws need a T10 Torx bit or Allen key to remove.

Disassembly Continued

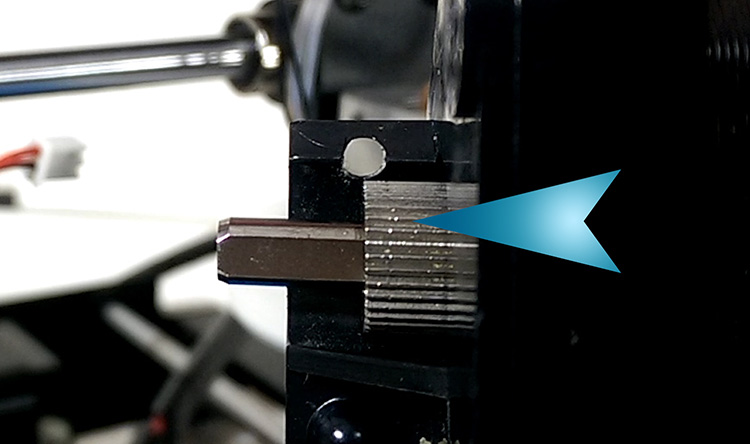

The moment I removed the fan and heat sink I found the problem. The filament was sitting to the side of the feeder gear so it’s no wonder the motor was going but nothing was happening. So now the question is why did this happen and how do we fix it. A little more disassembly is in order.

To get a clear look at the motor drive axle and the feeder gear we just need to remove the filament locking arm by removing this one screw. This one needs a T8 Torx bit or Allen key. Just make sure to hold on to it well because this spring will fly out on its own.

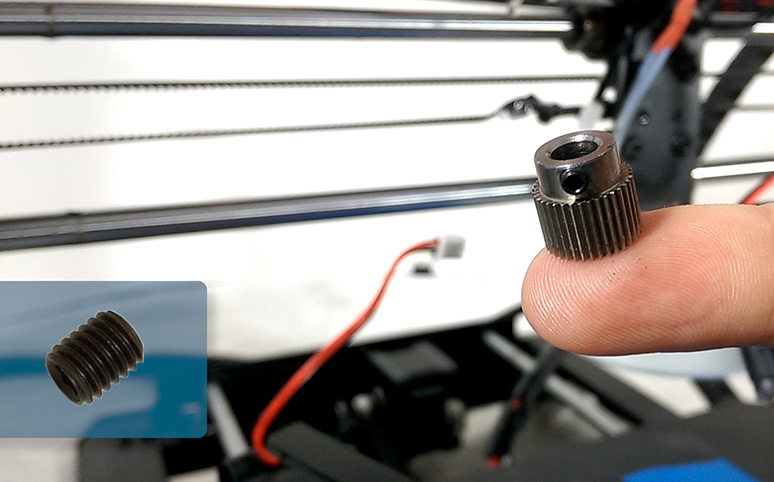

With the arm removed we can plainly see the issue. Looking down from above the gear has moved down the motor axle so that it no longer lines up with the filament guide hole. You can see where the gear had been grabbing on to the filament until now. It’s obvious that the gear is not locked in place anymore allowing it to slide down the axle thus letting the filament slip to the side of the gear where it can’t properly feed it or pretty much at all. The culprit of this is the set screw. This tiny screw tightens down on the flat portion of drive axle to keep the feeder gear from moving around but again it’s clear this set screw has become loose, I can only assume from hours of vibrations and back to back heat cycles.

The Fix

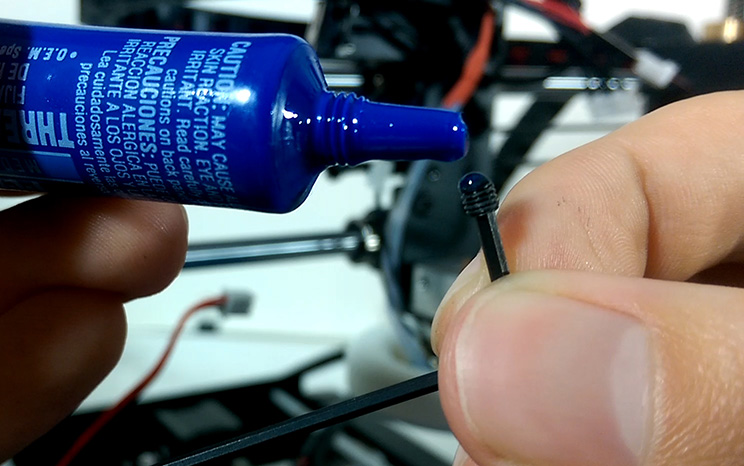

To fix this problem so that it hopefully won’t happen again I’m going to apply some Permatex brand Blue threadlocker to the set screw. Threadlocker is an adhesive designed to be applied to the threads of screws or bolts to prevent them from loosening over time due to vibration which is exactly what we want here. I chose the Blue variant over the Red because it still allows the ability to remove the set screw in the future if I need to, like in the case that I need to change the motor entirely. The Red version is basically permanent so servicing it in the future would be difficult.

I’m only going to apply a small drop on the bottom of the set screw hoping it will tack to the wall of the screw hole as I tighten it back in position. Before setting it completely we just need to slide the gear so that it completely overlaps the filament guide hole and now with a T7 Torx bit or Allen key we apply some torque to fix it in place. Now it’s time to reassemble everything.

Re-Assembly

Holding the filament locking arm and spring in place we put the screw back in place, this part if a little tricky because you have to compress the spring on one end of the arm while trying to put the screw back in place on the other end. Now sandwich the fan, heat sink, and motor back together as the two long screws are put back into position and done.

The threadlocker takes roughly 20 minutes to set and 24 hours to cure so while you can use the printer after 20 minutes go ahead a let it cure first.

Outcome

After several prints everything seems to be holding steady. I took the feeder assembly apart again to make sure the gear was still secure and it seems good.

I understand why this setup was used from the factory, because it was easy, but it seems like this would be a big issue going forward and without a solution like the application of threadlocker to the set screw this problem is inevitable for every printer with this setup. So if you feel comfortable taking apart the printer I would check on this before it messes up a print.

Now I can finally finish the pieces that were intended for this episode, more on that next time.