Intro

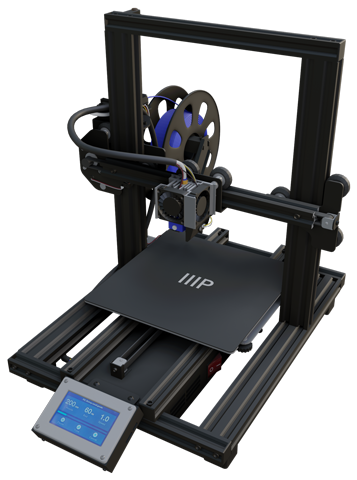

In part one we assembled the MP10, if you haven’t seen it read about the assembly process in part 1 here. Today we will turn the MP10 on and try out a few prints to see the quality out of the box and explore some of its unique features. We will be comparing the results to the V2 to see just how much better the MP10 is or not.

Full Review

Watch the overview video or keep reading the full article below

Table of Contents

Next Steps – SD Card

Let’s jump right into it by installing the included micro SD card. Popping in the SD card is straightforward, it’s spring loaded here which is different from the simpler slide it in of the V2 but like the V2 you insert the SD card with the connectors facing up. Not sure why this orientation feels so weird because it’s pretty common with other devices. Just pop it in and it’s secure, I prefer this setup over the V2.

Load Filament

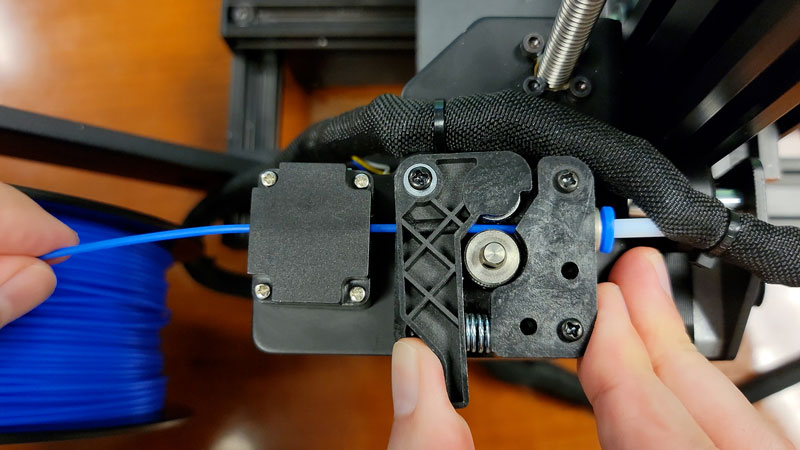

Next up let’s load the filament. I was going to use the provided filament but it was too tangled and I didn’t feel like messing with it so I threw on a fresh 1 kilo spool. Loading the filmant into the MP10 is significantly different from the V2. After mounting the roll you feed the filament through this block which houses the filament sensor, more on that later. From there slide it into the feed motor which unlike the V2 is located on the vertical frame instead of on top of the print head.

Partially compress the release lever as you feed through the filament, don’t try to completely squeeze the lever because it will push the tip of the filament away from the next opening. Now comes the interesting part, you have to feed the filament through this tube that leads down to the nozzle. You just have to feel your way as you feed the filament until it hits the end. I’ve noticed a small bump at the end that tells you you’re at the nozzle, that and you won’t be able to push any more filament in.

I’m not sure how I feel about this setup. I do like that the feed motor is directly aligned with the filament spool and the tube makes sure the filament doesn’t scrub against other components but swapping out the filaments will be more tricky than the V2 since you can’t see how much filament is in the tube. I’ll have to investigate the best way to get that done. Subscribe to make sure you don’t miss out on that videos!

Power On

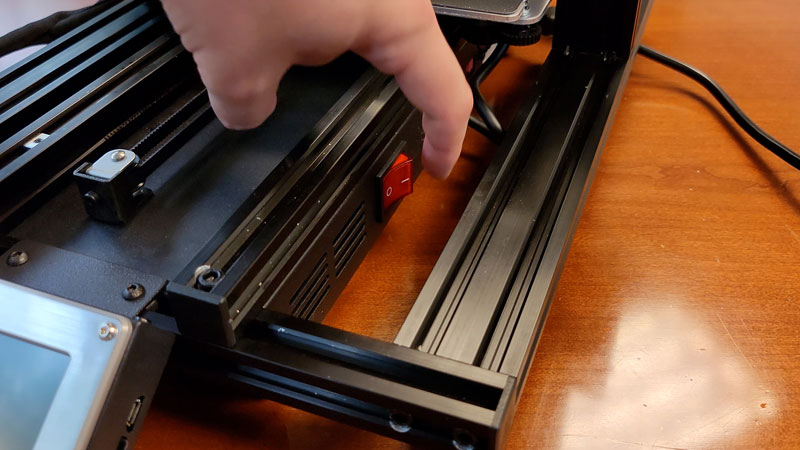

Let’s fire this thing up. On the right side of the PSU is a large red power switch, you may have to slide the bed out of the way to reach it. The position of the switch is a little cumbersome to get to but I guess there’s not too many other places on the PSU that’s any easier other than possibly on the back. Just be careful if the bed is hot.

Touch Screen and UI

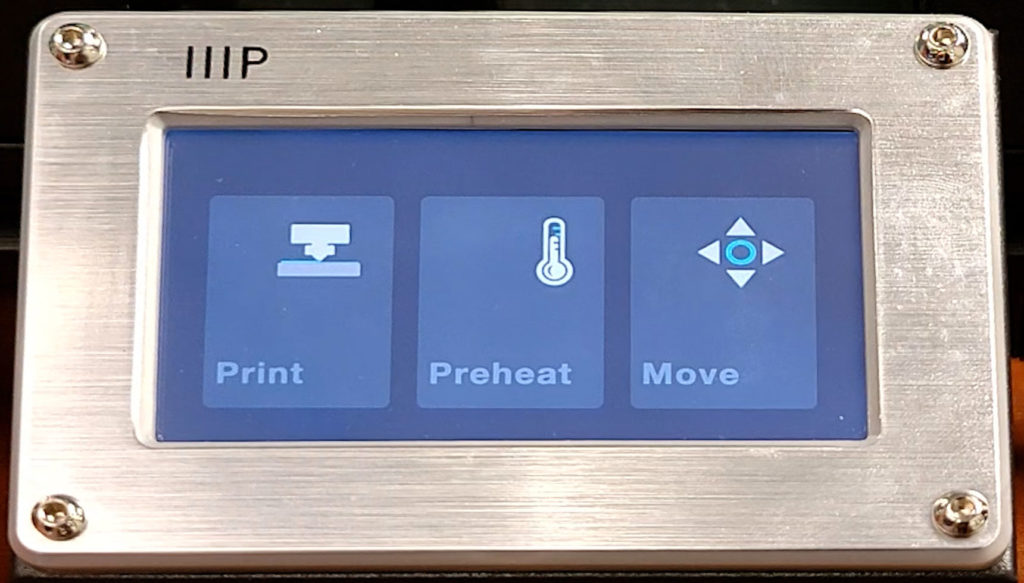

With the printer on we get to check out the completely different UI from the V2, it’s much simpler and of course touch screen! But unlike the touch screens on our smart phone this is a resistive touch screen which means you can literally use anything to press the icons. It is a little finicky when using your finger so I would recommend using a pen or even the included scrapper to navigate.

Menu Screens

Move

Let’s take a quick tour through the screens. Move, is the most interesting screen so let’s start there. From this screen we have the ability to retract or push the filament, move the print head left and right, up and down, and move the bed back and forth.

The home button moves the print head to its home position at the front left corner of the bed. We were able to do all of this with the V2 using the knob in a little more clunky way. What we weren’t able to do on the V2 is what we find under the Tune button.

Tune / Bed Level Correction

If we back out of the Tune screen and then go into the Preheat screen we are presented with a few options to preheat the printer. I like this setup because you can choose the exact temperature you want to heat the nozzle or bed instead of choosing a material default like the V2, although the model data dictates the temperatures anyway.

Preheat

If we back out of the Tune screen and then go into the Preheat screen we are presented with a few options to preheat the printer. I like this setup because you can choose the exact temperature you want to heat the nozzle or bed instead of choosing a material default like the V2, although the model data dictates the temperatures anyway.

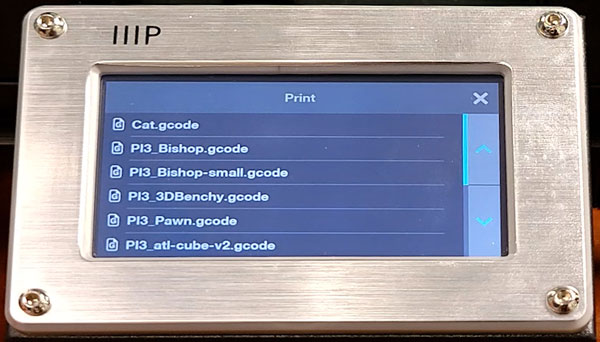

Printing

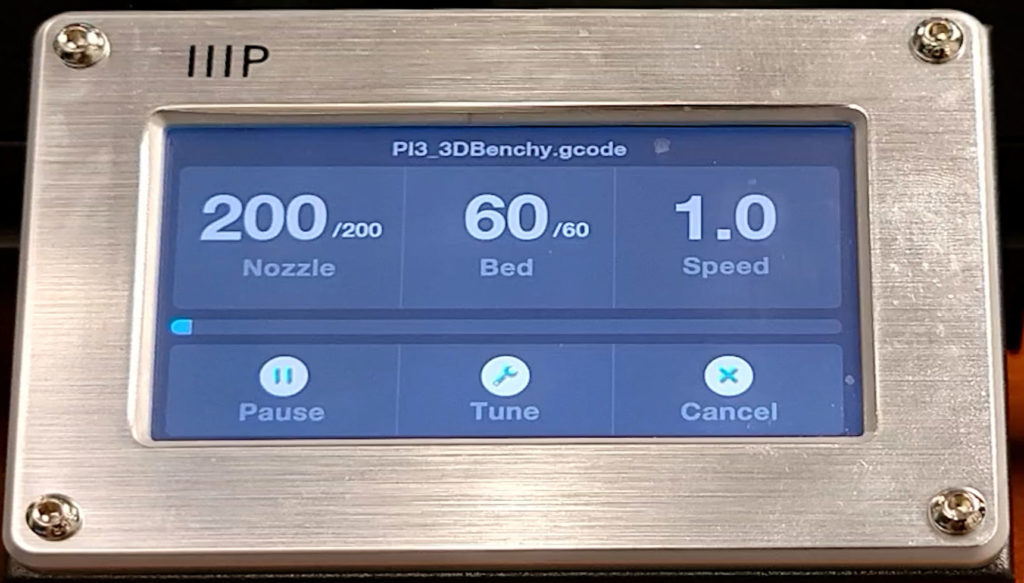

Just select a file and it’ll automatically get going. While the print screen has fewer details than the one on the V2, which included details like the coordinates of the print head, I guess that’s not ultimately very useful. So narrowing down what info is presented works here. Plus we have three more buttons we didn’t have on the V2. Obviously the Pause button allows you to pause and resume a print. You can use this feature to, for instance, swap out the filament if you want a different color.

The tune button takes us to the screen we saw earlier to fine tune the nozzle height while you’re printing, which again is awesome! If you start a print and notice it’s not adhering to the bed or the filament is too squished you can make those adjustments on the fly instead of having to cancel the print all together to make adjustments like you would have to with the V2. Like I said earlier though those adjustments won’t take effect until you confirm them. Lastly we have the Cancel button which is self explanatory.

One thing that threw me off at first was the lack of a print percentage reading that I was used to seeing with the V2 until I realized there’s a progress bar above the buttons that tells you how far along the print is and at the end it tells you how long the print actually took, neat.

Print Results

So now the reason why you probably clicked on this video. How do the prints from the MP10 compare to the V2. I used two models to make the comparison, the good ole Benchy tugboat and a model I made for a future project. These are both gcode files sliced up in Cura 4.6 with draft quality.

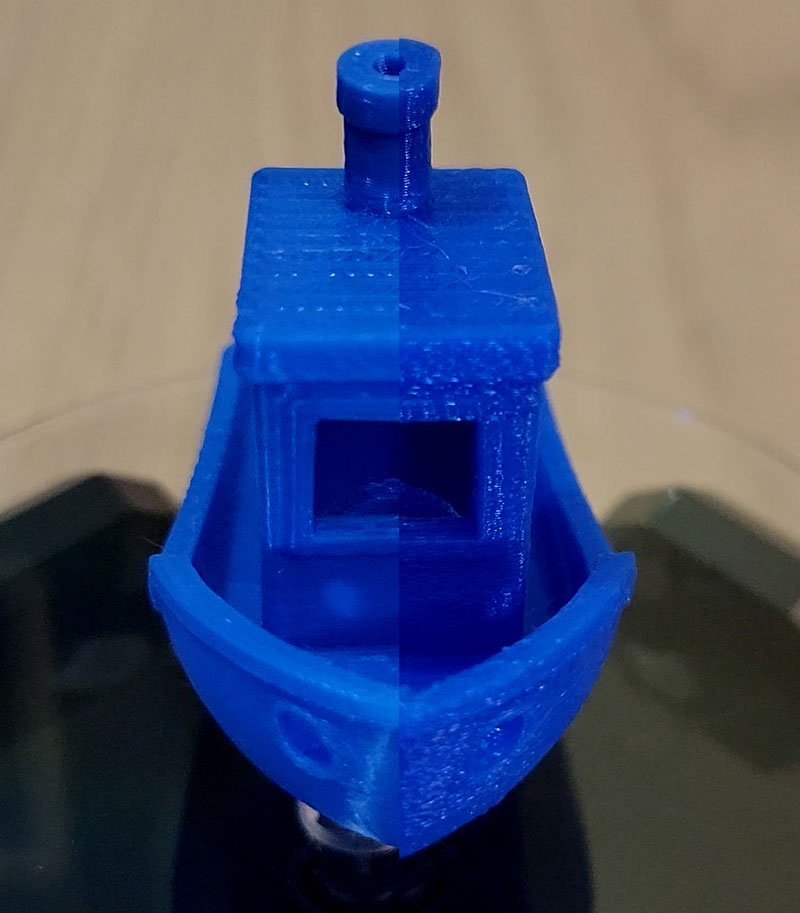

The Benchies

First up the Benchy and the comparison is striking to say the least. Many aspects of the Benchy have improved with the MP10. The hull is definitely smoother, not perfect but a lot better than the V2. Then there’s the improved definition of different parts like the holes for the anchor and the frames around windows and doors. The cabin in general is better defined and smoother than the V2, also there’s almost no stringing across the gaps compared to what we find on the V2. Again it’s not perfect but for a print out of the box with a sub $300 printer it’s pretty impressive.

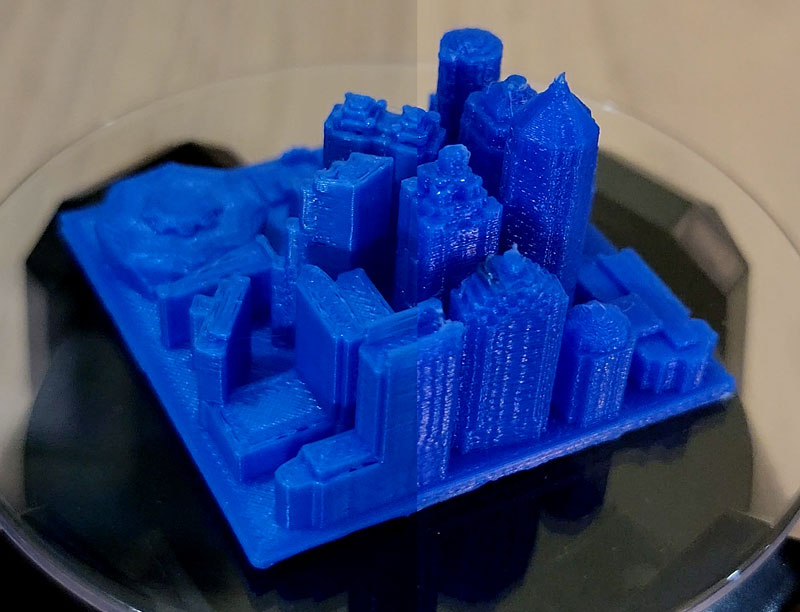

City Blocks

Let’s take a look at the other model. This miniaturized cityscape of downtown Atlanta is tricky to print due to the constant transitioning from building to building which typically leads to a horrific amount of stringing between each building. But as we can see the MP10 model turned out great compared to the V2. Just like the Benchy, all of the surfaces are much smoother and it printed much faster because of the improved print speed of the MP10.

Maker Pro 10 Mini User Manual - PDF

In-depth user manual that covers all most everything from un-packing and setup to 3D slicing program settings and fan speed configuration. Please read before using this printer.

Conclusion

It’s pretty obvious based on these two models that the stock MP10 is superior to the modified V2. The special features of the MP10 like the assisted bed leveling and being able to adjust the print head level on the fly makes this my new go to printer. I’m not sure if I should keep trying to improve the V2 or wholly move my main project prints to the MP10. There’s no harm in trying so we’ll see. At the same time modding the MP10 will only improve it further. More on that in the future.