Intro

In my first Creality article, we took a deep dive into the Creality Ender 3 V3 SE, from unboxing and setup to the first print and some solid early impressions. But as I mentioned then, there was one thing that really stood out while testing those first prints: the spool wobble.

Seriously, during fast moves, it was like watching a blender on top of the printer. All that rattling and those sympathetic vibrations feeding back into the frame, definitely not helping print quality.

So today’s video is all about how I tackled that problem with a super simple, custom one-piece spool holder mod. No screws. No tools. No more crazy shaking.

Full Guide

Watch the overview video or keep reading the full article below

Table of Contents

The Spool Holder Side Mount Mod

Instead of mounting the spool on top of the printer, where it gets violently shaken during fast movements, this design puts the spool off to the side in a clean and stable way. It uses the printer’s own weight to hold it in place. There are no screws, no bolts, it just slides around one of the rubber feet underneath and stays put.

It’s a super simple design with some key features that help this spool holder work so well with the Ender V3. At the top, it has a subtle inward V-shape that keeps the spool centered and continues to self-center during printing. It also makes mounting and unmounting spools a easy as it gets, no screwing on and off clamps or trying to align with cones or bearings like other mods. That being said, I will advise to mount the spool so that it feeds over instead of under, which I’m sure will trigger some people.

The overall thickness of the design gives it plenty of rigidity too, it doesn’t flex or sag, even when holding a full one-kilogram spool. And I was able to print mine with just a 20% infill, so it’s efficient without sacrificing strength. Lastly, the beveled lip on the top edge lets the spool spin surprisingly freely, even without adding any bearings like I used in previous mods.

Printing the Mod

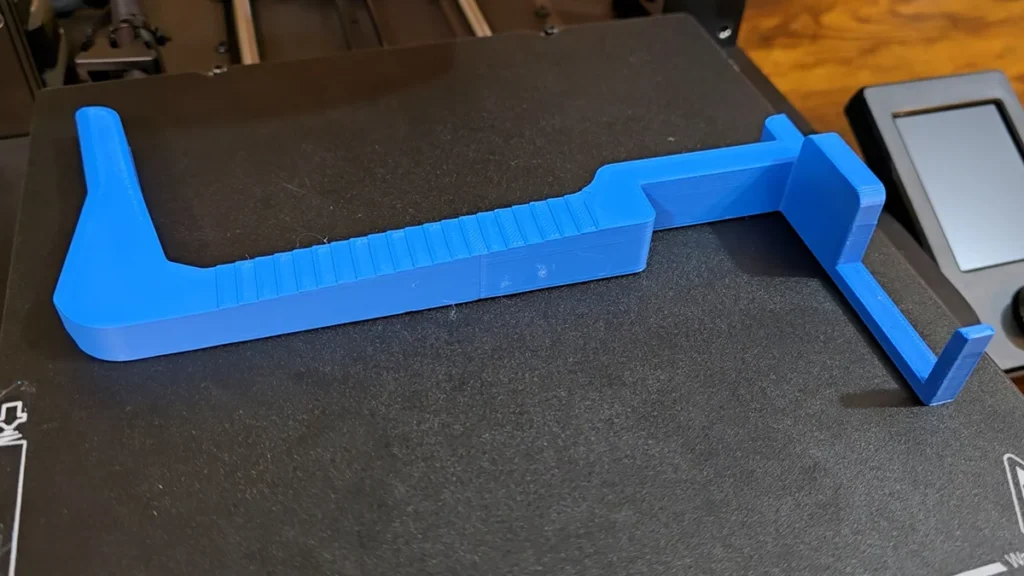

Now, one thing to know is that this model is big. On its longest side it measures in at just over 200mm, which means it barely fits on the Ender SE’s bed. Because of that, you won’t be able to use a skirt or raft as an adhesion layer, you may get away with a very small brim.

Installing this mod is as simple as it gets, you just slide the holder under the back-right corner of the printer, and it stays firmly in place on its own thanks to the hook that grips around one of the rubber feet and the weight of the printer.

Just keep in mind, that this design is custom-made specifically for the Ender 3 V3 SE, so it may need customization to fit properly on any other printer, but I feel the design concept can be adapted quickly to almost any printer.

Guiding the Filament

The whole reason I wanted to move the spool to the side in the first place was actually inspired by my other printer, the Monoprice MP10 Mini. That printer comes stock with a side-mounted spool holder, which I always thought was a cleaner, more stable, and more compact setup. The difference is that on the MP10, the filament feeds through a built-in tube that guides it from the side all the way to the print head. The Ender 3 doesn’t have that, so I needed a new solution. And that’s where this filament guide comes in.

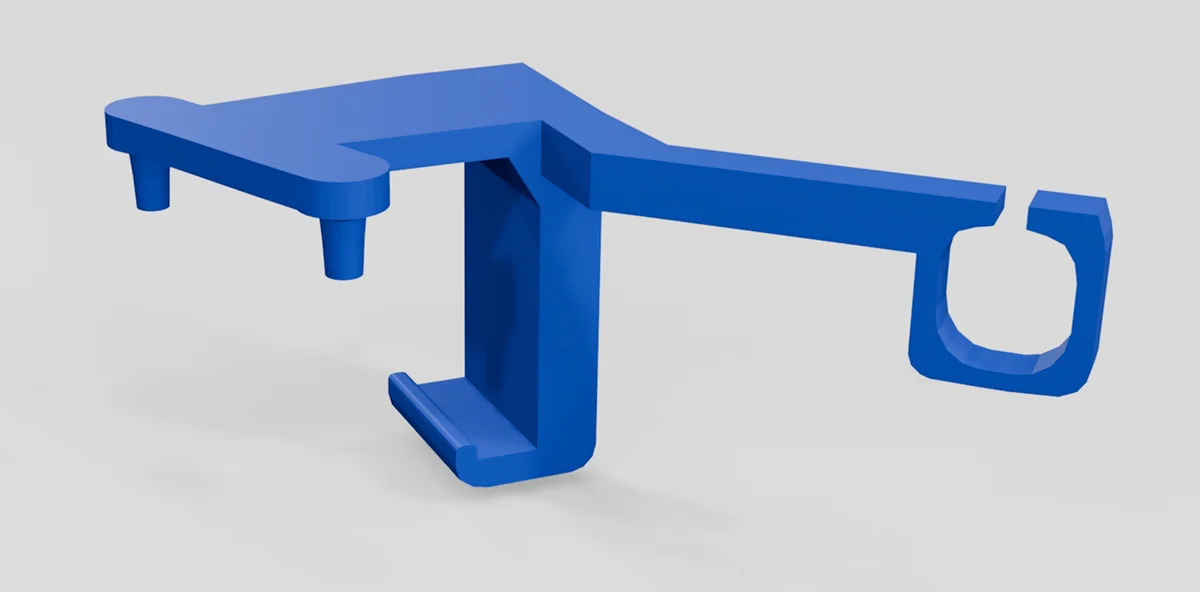

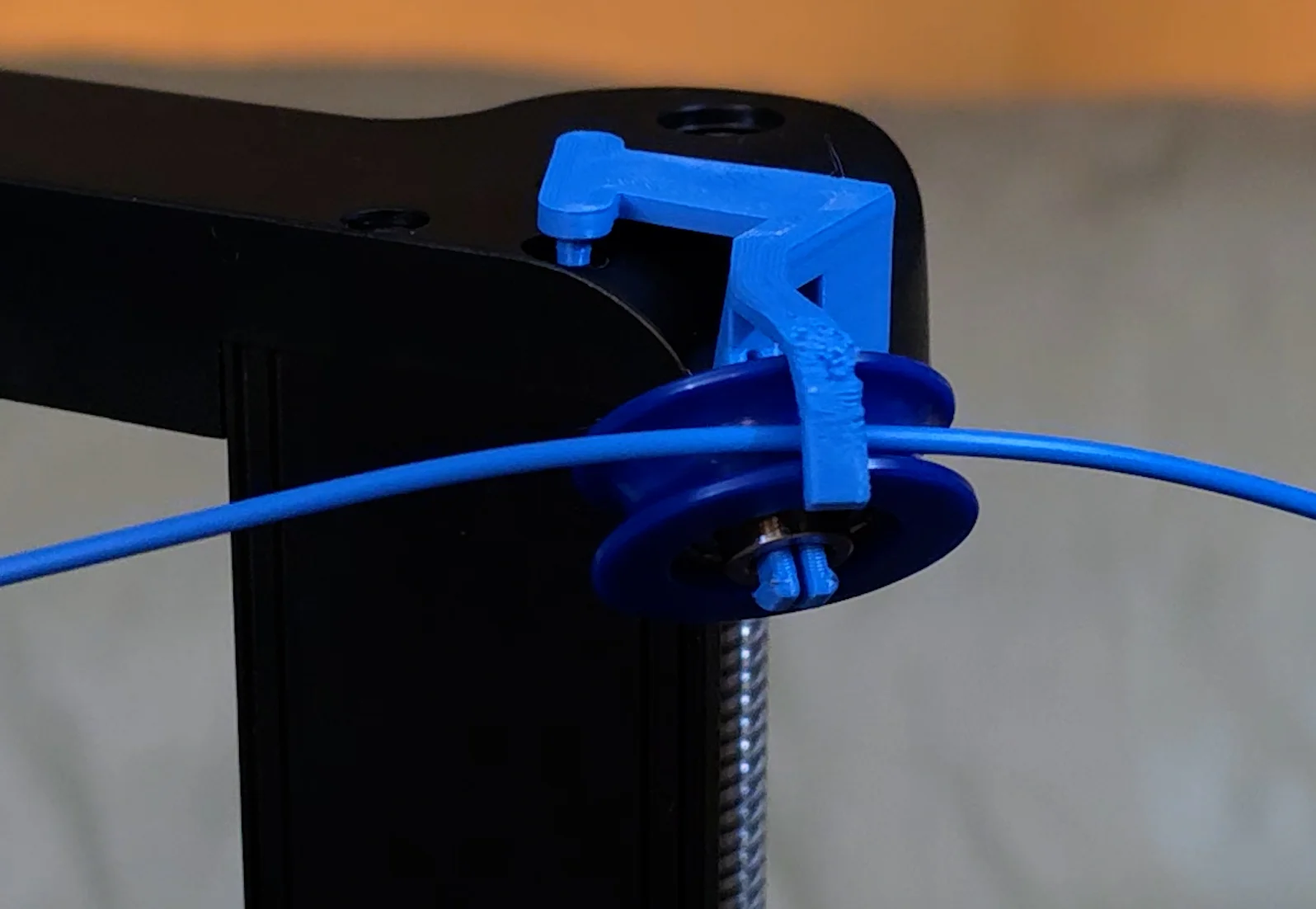

To make the side-mounted spool work smoothly, I designed a small guide that clips onto the edge of the top gantry. Its job is to route the filament around the frame cleanly, so it doesn’t scrape, snag, or get tugged awkwardly on its way to the extruder. The angle of the guide arm was specifically designed to help the spool unwind evenly and straight; without the guide, the spool can get pulled to one side which may cause some feeding issues.

What’s really nice is that the guide simply snaps into place with a lip underneath the frame and two studs on top that fit into the existing bolts holding the gantry together. Just like the spool holder you don’t need any tools or replacement screws and the snap itself when it slots into place is so satisfying. It’s a snug fit, it’s not going anywhere. I did make two versions of the guide. One has a simple loop on the arm where all you have to do is just slide the filament into the opening at the top and it’s good to go.

Ultra Filament Guide

But if you’re looking for ultra-smooth filament mobility then the other version is for you and features a barbed clip to securely slide on a U-groove bearing and also includes a guard to keep the filament in place. To install the bearing, pinch the clip and slide on the bearing then push the filament under the guard until it sits on groove of the bearing and you’re done. I love the tolerances on this thing. Just enough room for the bearing to spin freely while keeping the filament from sliding out, it’s a beautiful thing. You can find the bearing I used on Amazon. I did design this version around that specific bearing, but you can modify it to fit another bearing of your choosing, just keep in mind you’ll have to update the design of the barb and the guard to accommodate any other size bearings.

One word of note, make sure that the guide is completely cooled down before attempting to snap it in place. I learned that from experience.

This model is a little more complicated of a print because of the overhangs. You will need to include supports. I ended up using the default tree support settings in Cura 5.9 and it turned out great for me. It’s also printed upside down to make things a little bit easier.

So with these two mods, the side-mounted spool holder and the clip-on filament guide, the whole setup becomes clean and extremely stable. It honestly made a huge difference for me. The printer looks better, runs smoother, and I don’t get nervous watching the spool shake like it’s about to launch off the frame. Here is a side-by-side comparison, with the side mount it’s rock solid compared to the top mount, no more excessive wobbling! I think one feature of this setup that aids in the added stability is that there’s a lot more slack in the filament so that when the extruder does move around, especially in quick bursts, it’s not constantly yanking on the spool and making it wobble more violent.

Downloads

Download the files from Printable or Thingiverse

GCodes

220 S100 ;Reset Feedrate

M221 S100 ;Reset Flowrate

G28 ;Home

M420 S1; Use saved mesh leveling data

G92 E0 ;Reset Extruder

G1 Z2.0 F3000 ;Move Z Axis up

G1 X-3 Y20 Z0.28 F5000.0 ;Move to start position

M190 S{material_bed_temperature_layer_0} ; Set bed temperature and wait

M109 S{material_print_temperature_layer_0} ; Set hotend temperature and wait

G1 X-3 Y100.0 Z0.28 F1500.0 E15 ;Draw the first line

G1 X-2 Y100.0 Z0.28 F5000.0 ;Move to side a little

G1 X-2 Y20 Z0.28 F1500.0 E30 ;Draw the second line

G92 E0 ;Reset Extruder

G1 E-1.0000 F1800 ;Retract a bit

G1 Z2.0 F3000 ;Move Z Axis up

G1 E0.0000 F1800

G91 ;Relative positioning

G1 E-2 F2700 ;Retract a bit

G1 E-2 Z0.2 F2400 ;Retract and raise Z

G1 X5 Y5 F3000 ;Wipe out

G1 Z10 ;Raise Z more

G90 ;Absolute positioning

G1 X0 Y{machine_depth} ;Present print

M106 S0 ;Turn-off fan

M104 S0 ;Turn-off hotend

M140 S0 ;Turn-off bed

M84 X Y E ;Disable all steppers but Z

Conclusion

I’m honestly really happy with how this turned out, it’s clean, simple, and it just works. Coming up with the idea and iterating through different versions is exactly what makes 3D printing so much fun for me. The STL files for the spool and both versions of the filament guide can be found on my Printables profiles page.

- FASTER AND LIVELY PRINTING EXPERIENCE: Ender 3 V3 SE 3d printer can print at up to speed 250 millimeter per second with acceleration 2500 millimeters per square second, faster than most of printers on the market. You can complete models efficiently, saving time to wait for print jobs. Moreover, it can keep good printing quality at the same time. The optimized UI uses motion graphics to display the leveling process and other parameters, so you will know how the printer is doing at a glance, providing you a perfect printing experience

Frequently Ask Questions

The Side Mount Spool Holder is a custom 3D-printed side-mount spool holder designed specifically for the Ender 3 V3 SE. It relocates the spool from the top of the printer to the side, reducing vibration and improving stability during prints.

Mounting the spool on the side helps reduce wobble and sympathetic vibrations that can affect print quality. It also lowers the center of gravity and makes filament feeding more consistent, especially at higher print speeds.

The Side Mount Spool Holder mod was custom designed for the Ender 3 V3 SE, and it hooks securely onto the printer's existing rubber feet. It may not fit other models without modification.

Infill: 20% is strong enough for both parts.

Supports: No supports needed.

Adhesion: Print the spool holder flat with no brim or skirt, as it barely fits on the Ender 3 V3 SE bed.

Material: PLA, PETG, or stronger filaments like ABS will work well.